تقوية العمود

تغليف الأعمدة بألياف الكربون وتحسين الأداء الزلزالي

من ناحية، يُمكن لتغليف ألياف الكربون المُقوّاة بألياف الكربون (CFRP) أن يزيد من قوة الضغط المحوري للخرسانة إلى حدٍّ ما. ومن ناحية أخرى، يُمكن لتأثير الكبح العرضي لتغليف ألياف الكربون على الأعمدة أن يُحسّن بشكل ملحوظ من ليونتها تحت الأحمال الأفقية، ويُلبي متطلبات ليونة نسبة الضغط المحوري.

في هيكل إطاري من الخرسانة المسلحة متعدد الطوابق، وُجد أن قوة الخرسانة لتسعة أعمدة إطارية لا تلبي متطلبات التصميم أثناء قبول البناء، مما أدى إلى ارتفاع نسبة الضغط المحوري بشكل مفرط، مما لم يُلبِّ متطلبات اللدونة التي تتطلبها القيمة الحدية لنسبة الضغط المحوري. من ناحية، يُمكن لتغليف الخرسانة بألياف الكربون المقواة بألياف الكربون زيادة قوة الضغط المحوري للخرسانة إلى حد ما. من ناحية أخرى، يُمكن لتأثير الكبح العرضي لتغليف الأعمدة بألياف الكربون أن يُحسِّن بشكل كبير من لدونتها تحت الأحمال الأفقية، ويلبي متطلبات اللدونة لنسبة الضغط المحوري.

بحساب قدرة التحمل واللدونة، تُغلَّف ثلاثة أعمدة ذات قوة أقل بثلاث طبقات من تغليف ألياف الكربون المقواة بألياف الكربون على طول ارتفاع العمود. أما بالنسبة للأعمدة الستة الأخرى، فسيتم تغليف طبقتين من تغليف ألياف الكربون على طول ارتفاع العمود.

تحليل قدرة تحمل ومتانة تسليح غلاف CFRP

بعد تسليح غلاف CFRP بألياف الكربون، يُمكن تحسين قدرة القص ومتانة أعمدة الإطار بشكل ملحوظ.

يبلغ الهيكل الأصلي 800 × 800 مم، بارتفاع 3.6 متر. ووفقًا لنتائج البحث ذات الصلة، يُمكن تحسين قدرة القص لغلاف CFRP عن طريق حساب الضغط.

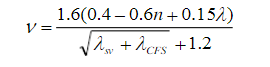

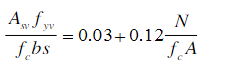

بالنسبة لمخطط التغليف الكامل للمشروع، الصيغة هي

قوة التحمل التصميمية للخرسانة هي C40. ووفقًا لهذا الحساب، يجب أن تكون قدرة القص للعمود الواحد 1312 كيلو نيوتن. بالنسبة للأعمدة الثلاثة ذات القوة الأقل، تكون أقل قوة للخرسانة 28.3 ميجا باسكال، وقوة القص 1031 كيلو نيوتن بدون تسليح. عند لف ثلاث طبقات من البلاستيك المقوى بألياف الكربون (CFRP)، تكون الزيادة في قدرة التحمل 319 كيلو نيوتن، وتكون القدرة الكلية 1350 كيلو نيوتن، وهي أعلى من قدرة التحمل التصميمية. بالنسبة للأعمدة الستة الأخرى، تكون الحد الأدنى لقوة الخرسانة 35 ميجا باسكال، وتكون قوة القص 1209 كيلو نيوتن بدون تسليح. عند لف طبقتين من ألياف الكربون، تكون الزيادة في قدرة التحمل 246 كيلو نيوتن، وتكون القدرة الكلية 1455 كيلو نيوتن، وهي أعلى من قدرة التحمل التصميمية.

وفقًا لنتائج الاختبار، عند تحديد نسبة الضغط المحوري، يزداد معامل ليونة أعمدة التغليف المصنوعة من البلاستيك المقوى بألياف الكربون خطيًا مع قوة القص ومعامل الانحناء الضعيف Vs/Vm. عندما تكون نسبة الضغط المحوري 0.48، تُطبق صيغة التركيب التالية.

μ=-1.278+5.233Vs/VM

يتضح من الصيغة العليا أنه كلما زادت قوة القص لألياف الكربون، زادت نسبة Vs/VM ومعامل اللدونة.

ووفقًا للأبحاث، عندما يبقى معامل اللدونة ثابتًا، فإن معامل خاصية الركاب يرتبط بالعلاقة التالية مع نسبة الضغط المحوري:

تُظهر الصيغة العليا أنه عند زيادة نسبة الضغط المحوري، يجب زيادة نسبة الطوق بشكل مناسب للحفاظ على معامل اللدونة دون تغيير.

وفقًا للتقدير المُحافظ، وبافتراض أن نسبة الضغط المحوري للأعمدة تزداد بمقدار 0.3 نتيجةً لانخفاض قوة الخرسانة، فإن الزيادة المُقابلة في معامل خصائص الركاب هي 0.066، ومعامل خصائص الركاب الجديد لـ CFRP هو 0.097، وهو ما يُلبي المتطلبات تمامًا.

يتضح من التحليل السابق أنه يجب تحديد كمية لف CFRP وفقًا لقدرة التحمل ومؤشر اللدونة عند تقوية أعمدة الخرسانة الخرسانية المسلحة بلف CFRP لتحسين قدرتها على تحمل الزلازل.