محاليل

تميل مجموعة أعمال Horse Construction إلى جميع أنحاء العالم وتقدم الخدمات لآلاف العملاء من خلال المنتجات ، والإرشادات الفنية المتخصصة في مجال الإنشاءات ، ونحن نشهد تطور العلامة التجارية الصينية معهم.

The emergence of prestressed FRP laminate has greatly helped solve the FRP strengthening problems. The biggest breakthrough of prestressed FRP laminate is to completely change the characteristics of passive reinforcement of materials, and play an active role in strengthening the structure by prestressing technology.

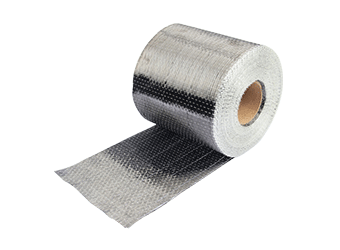

With the increasing of structural diseases and aging, the repairing and reinforcing engineering of the structure is also increasing exponentially. The development of reinforcement industry has led to the use of many new technologies, from once only using reinforced concrete for reinforcement, evolved into a variety of new materials, new technology widely used. The advancedcarbon fiber fabric which we often mention are one of the most representative materials for concrete strengthening.

Carbon fiber reinforced polymer (CFRP) fabric has the characteristics of light weight, high strength, good quality, and easy construction. High strength carbon fiber sheet can effectively act on the bending structure, improve the bearing capacity and extend the life of the structure, especially for various special sections. However, the seemingly high-quality carbon fiber cloth still has drawbacks that affect the structural reinforcement.

Disadvantages of carbon fiber fabric for strengthening

Firstly, the CFRP sheet is used to reinforce the structural members, and the increase of normal section bearing capacity should not exceed 40%, and the shear bearing capacity should be checked. This regulation is designed to prevent the flexural members from shear failure when the bearing capacity is increased. Only 40% of the increase will limit the exertion of CFRP strength, resulting in the waste of high strength materials.

In addition, the two force is also one of the important reasons that carbon fiber cloth can not give full play to its strength. The code requires that unloading should be carried out first when carbon fiber cloth is used for construction, so as to reduce the influence caused by secondary force. Secondary force, in short, refers to the common bending structure such as beams, plates, under the action of the upper load will occur tensile deformation. If CFRP is not unloaded and directly bonded, the tensile deformation of CFRP will lag behind the deformation of the beam and plate, resulting in CFRP deformation only after further deformation of the beam and plate, which will provide tensile stress for the beam and plate. Secondary force will seriously affect the strength of carbon fiber cloth, and even cause the structure to take precedence over the failure of carbon fiber cloth.

In fact, the strength of CFRP is also related to another factor, that is, the reinforcement ratio of the original structure. Under the limit state, the strength of CFRP sheet is limited by the deformation of the original structure, which is directly related to the reinforcement ratio of the original structure. If the ratio of reinforcement in the original structure is high, the stress produced by CFRP in the ultimate state will be low; if the ratio of reinforcement in the original structure is low, the stress produced by CFRP in the ultimate state will be high, and the strength will be fully exerted.

New solutions

It can be seen that the reason why there will be many drawbacks of carbon fiber cloth, in the final analysis, or because the reinforcement is too "passive". This common problem exists in a series of reinforcement materials, such as carbon fiber sheet, which can only improve the bearing capacity of the structure, but can not improve the internal stress state of the structure. Therefore, more effective reinforcement methods should be adopted either to improve material utilization or to improve the internal force of the structure.

The emergence of prestressed FRP laminate has greatly helped solve the above problems. The biggest breakthrough of prestressed FRP laminate is to completely change the characteristics of passive reinforcement of materials, and play an active role in strengthening the structure by prestressing technology. Prestressed FRP laminate can effectively improve the stress state of the structure, actively improve the bearing capacity of the structure, reduce the burden of the structure. At the same time, the prestressed FRP laminate can give full play to the material performance, and also has excellent effect in resource utilization.

يمكنك العثور على أي شيء تحتاجه هنا ، ولديك ثقة في تجربة هذه المنتجات ، وسوف تجد الفرق الكبير بعد ذلك.

تستخدم المواد البولیمریة المسلحة بألیاف الکربون في العدید من تطبیقات الهندسة الإنشائیة کتدعیم الأعمده، الکمرات، الجدران، البلاطات و الأسقف في المنشآت و المباني

صفح البوليمر المقوى بألياف الكربون (CFRP) للبلاطة ، وتعزيز شعاع

لاصق شرائح FRP عبارة عن لاصق وراتنجات متغیرة الانسیابیة مكونة من مكونين ، يستخدمان بشكل أساسي في ربط شرائح FRP. ينتج عن الجمع بين عجينة بيضاء (المكون A) ومعجون رمادي (المكون B) ، معجون رمادي فاتح.